SPC SOLUTION BRIEF FOR SAP ERP

Abstract

When sending a Purchase Order or a Release to a supplier, SAP ERP typically shows the delivery date as the date that the goods are expected to arrive in-house on the documentation. SAP ERP calculates the delivery date from the demand date using the planned delivery time on the material master. The deliery date is then updated in the procurement element (PO or Release).

Example: We need 100 PCE of Material A on May 26, 2021. The planned delivery time is 42 Days (6 Calendar Weeks). SAP calculates the latest release date for the PO to be April 14, 2021. On April 14, we send a PO to the supplier indicating the delivery date of May 26,2021.

With certain INCO Terms such as Ex Works or Free Carrier, the supplier interprets this date as the date the goods need to be shipped from the suppliers facility, as the supplier is not responsible for transportation. With longer transportation times, there can be a significant mismatch in expectations. If the supplier ships on the date stated on the PO or Release, especially for overseas shipments, we can be sure for the goods to arrive late.

Process Outline

We will start first with describing the important components of routes in SAP. For the ease of reading, we will refer to the example of a purchase order (PO) in this process outline.

What Is A Route In Sap

A route describes the mode and means of transportation and the time required for the shipment of items from the point of origin to the final destination.

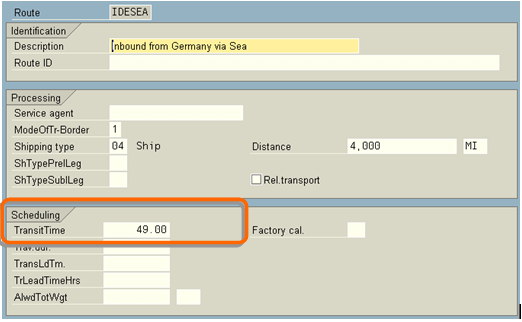

For the purpose of presenting suppliers with a ship date on the print form of a PO, a simplified route definition is used. The critical element for the route is the transit time.

The transit time is used to subtract from the original delivery date on the PO to show the supplier when the goods need to be shipped based on the applicable route.

For this particular example, routes are coded as a 1+2+3 character code (DCCTTT)

- I/O = Direction Inbound / Outbound

- DE/GB/FR/… = Country of departure

- SEA/FDX = Transportation mode

We won’t be using legs, stages, or transportation connection points to keep things simple.

Determining The Applicable Route

Several factors play a role in determining what route is applicable in a specific scenario.

- Transportation zones

- Shipping Instructions

- Transportation groups

- Weights

Transportation Zones

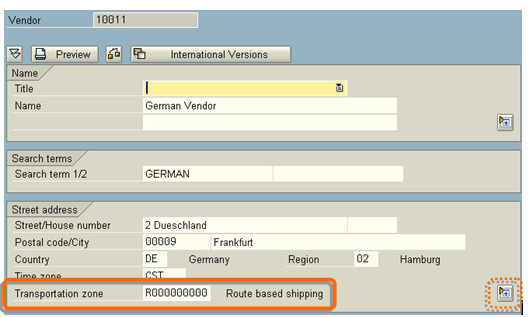

Origin and destination address both need to have a transportation zone assigned. The transportation zone is maintained in the master address data (vendor, plant, customer, etc…).

To distinguish between vendors that require a route-based ship date on the PO rather than a delivery date, we define that the transportation zone of the vendor master has to start with the letter “R”.

We can now create a generic transportation zone “R00000000” that can be utilized in the following countries.

- CA R000000000 Route based shipping

- CN R000000000 Route based shipping

- DE R000000000 Route based shipping

- FR R000000000 Route based shipping

- GB R000000000 Route based shipping

- US R000000000 Route based shipping

The transportation zone for route-based supplier ship dates is maintained in the address data on the vendor master:

![]() You may have to press the section expansion button to access the transportation zone field.

You may have to press the section expansion button to access the transportation zone field.

Shipping Instructions

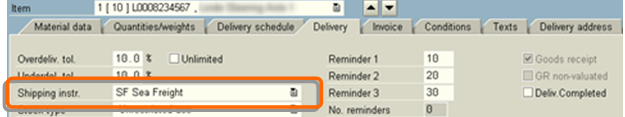

Routes are also be defined by shipping instructions. We use two shipping instructions to be utilized in the route determination for our sample process:

- FE FedEx Intl Economy

- SF Sea freight

Shipping instructions are entered directly on the line item of the purchase order:

Transportation Groups

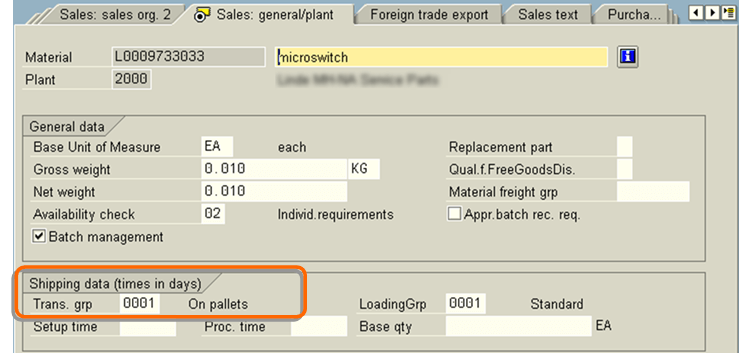

We will make use of the standard SAP transportation groups. These are

- Standard Transport

- Special Transport

Transportation groups are assigned on the material master in the Sales: General/Plant view

Weight

The route determination can also be influenced by weights. In route determination, weight groups can be defined. For our example, we are not going to consider weights.

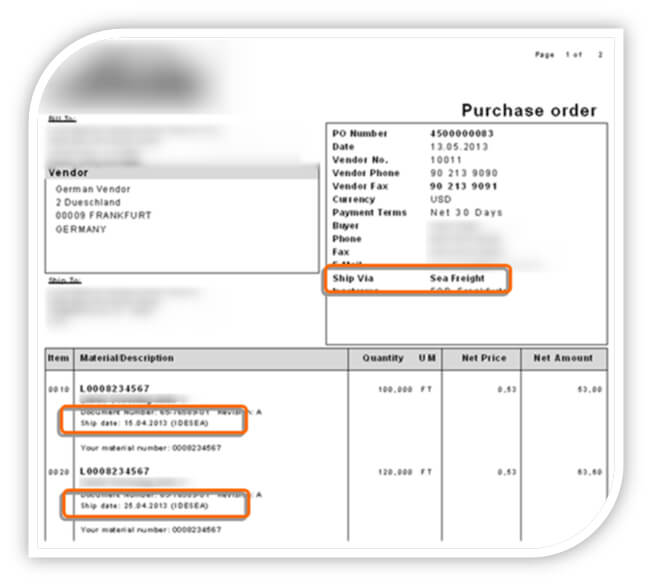

Effect Of Routes On Purchase Order Output

If all of the influencing factors have been maintained and entered, either as master data or on the PO, the PO output will recognize these elements and calculate a supplier ship date.

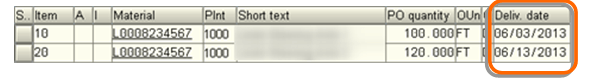

The ship dates are calculated on a header level if all items have the same transportation relevant data, or individually for each item:

for scheduled delivery dates of

Please note the difference between European and US Date notation – The PO Form shows the European notation as 15.04.2013 for item 10 which would be 4/15/2013 US.

The example shows that we advise the suppier to ship the materials at such time that the transportation time is considered and the goods will arrive when we identified the demand.